Why Pea Protein? Here's Our Story.

EXPLORE HOW WE MAKE IT!!

Factory Visit & Production Oversight

Step 1: R&D & Formula Development

This is where the magic happens. Our Research & Development (R&D) team carefully experiments with different ingredients, textures, and flavors to meet our high standards. Every batch is tested for taste, nutrition, and mixability before we approve it for production.

Step 2: Raw Material Receiving & Inspection

Before production begins, all raw materials are delivered and stored in our certified warehouse. Each ingredient undergoes strict inspection for quality, hygiene, and accuracy—ensuring only the best goes into every batch of our protein.

Step 3: Filling & Sealing

Each batch of our protein is carefully filled and sealed into individual sachets using high-precision machines. This ensures accurate serving sizes and maintains freshness and hygiene in every pack.

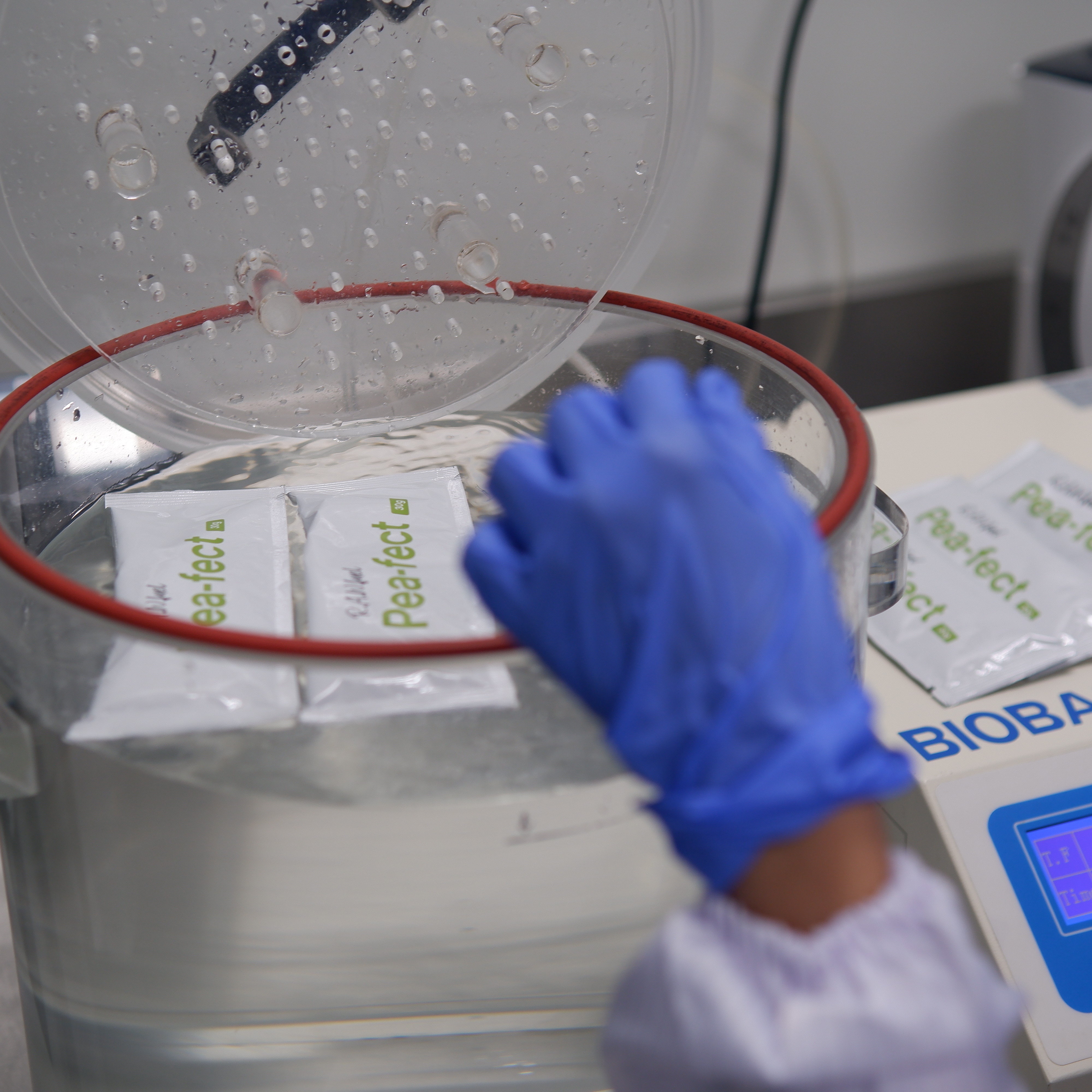

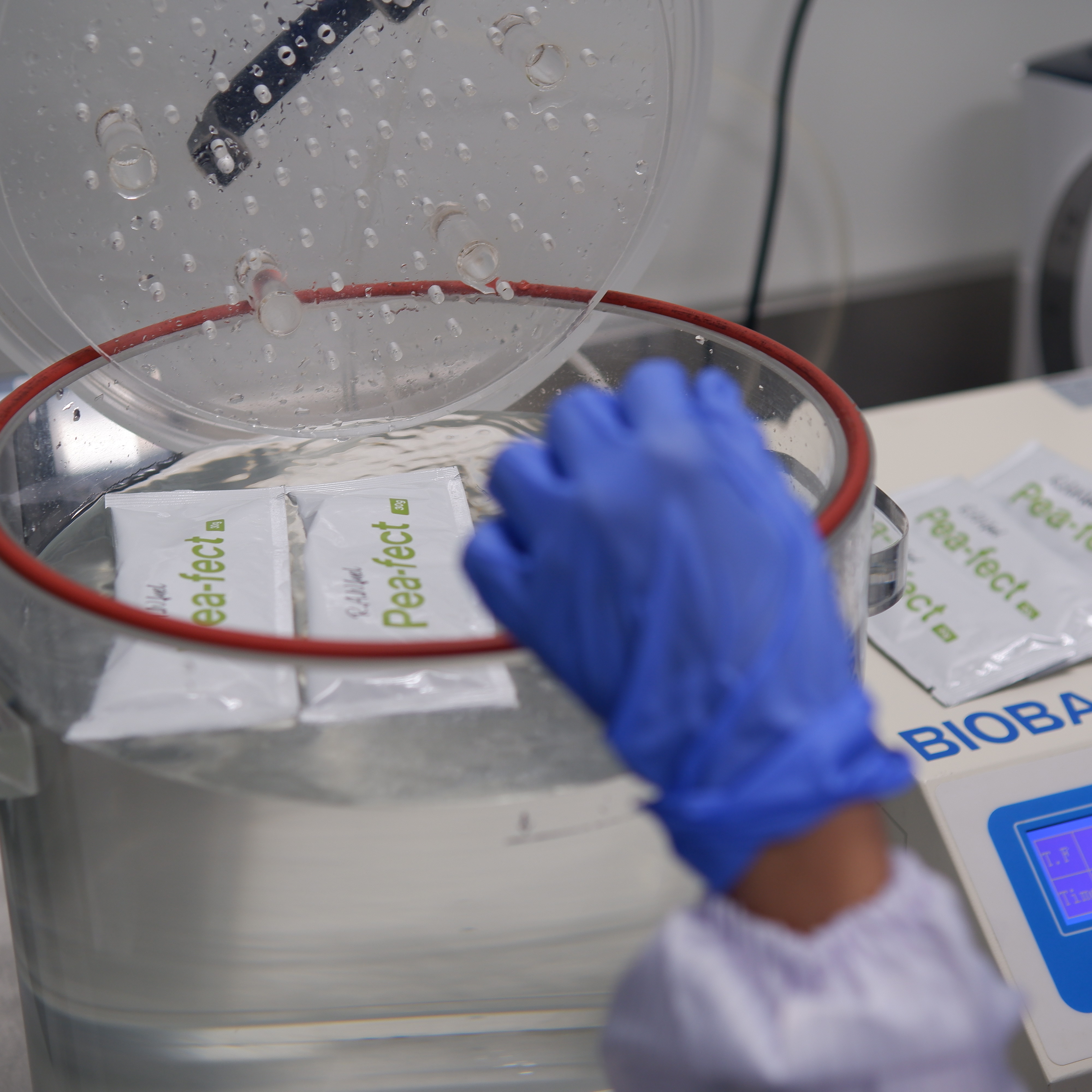

Step 4: Pressure Seal Test

To ensure our sachets are travel-safe and airtight, each batch goes through a burst challenge using high-pressure air. This test helps us detect any potential leaks or weak seals—if bubbles appear, it means the sachet isn’t up to standard. Only those that pass make it to you.

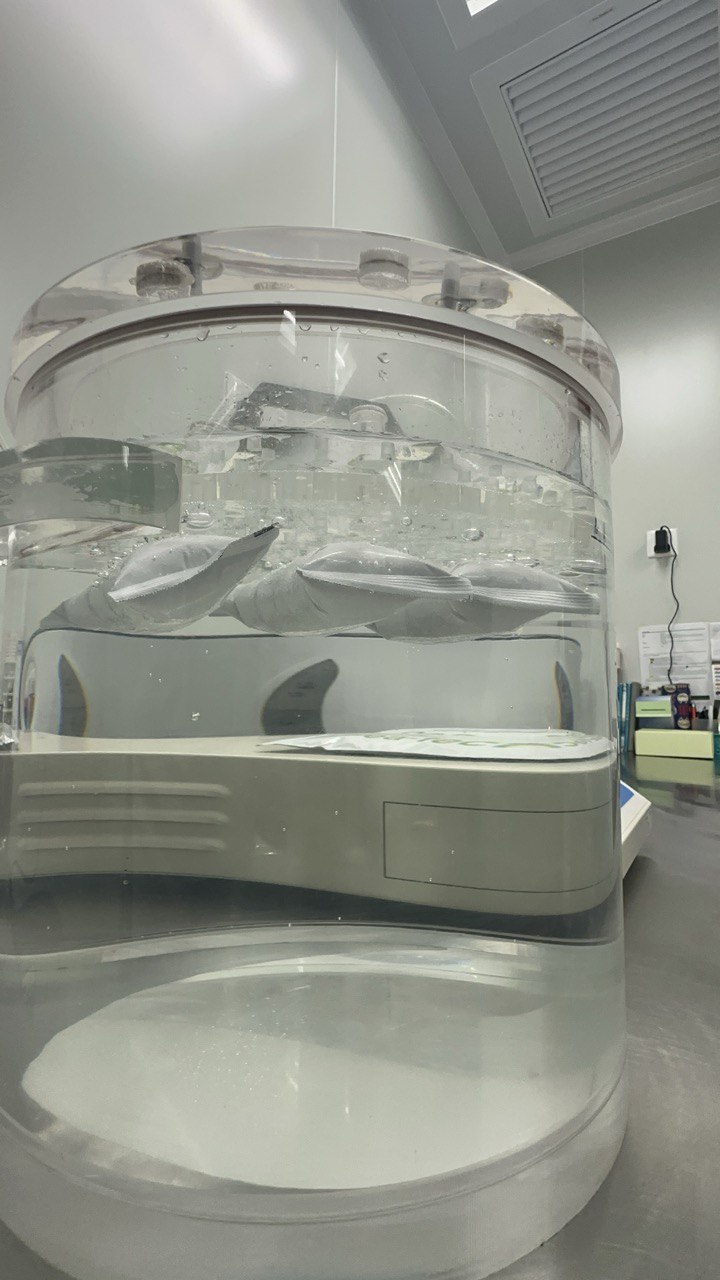

Step 5: Heat Stability Test

We subject our protein sachets to high-temperature conditions to simulate environments like hot car trunks or tropical climates. This ensures the formula remains stable, effective, and safe—without clumping, separating, or losing its nutritional integrity. Quality you can count on, even under heat.

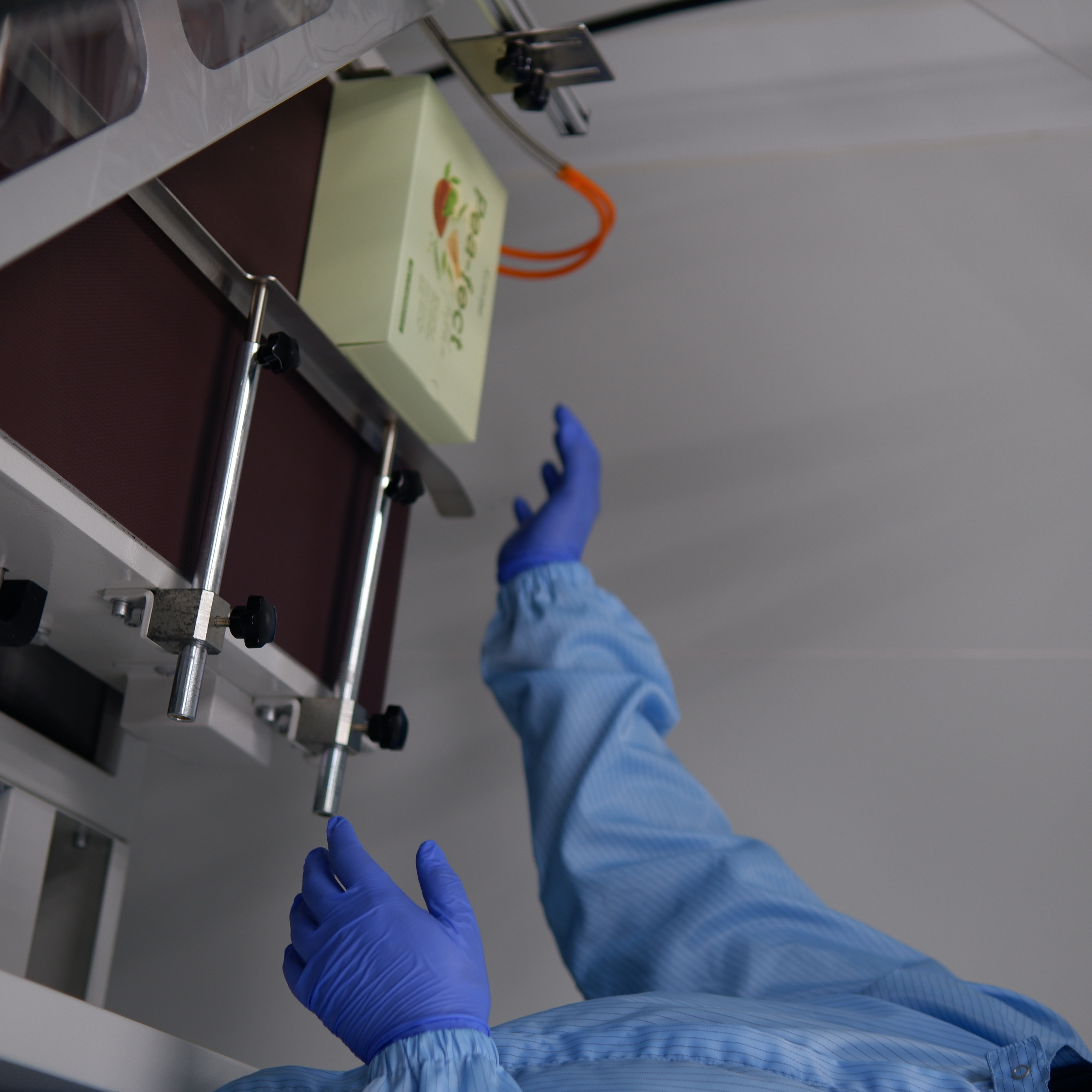

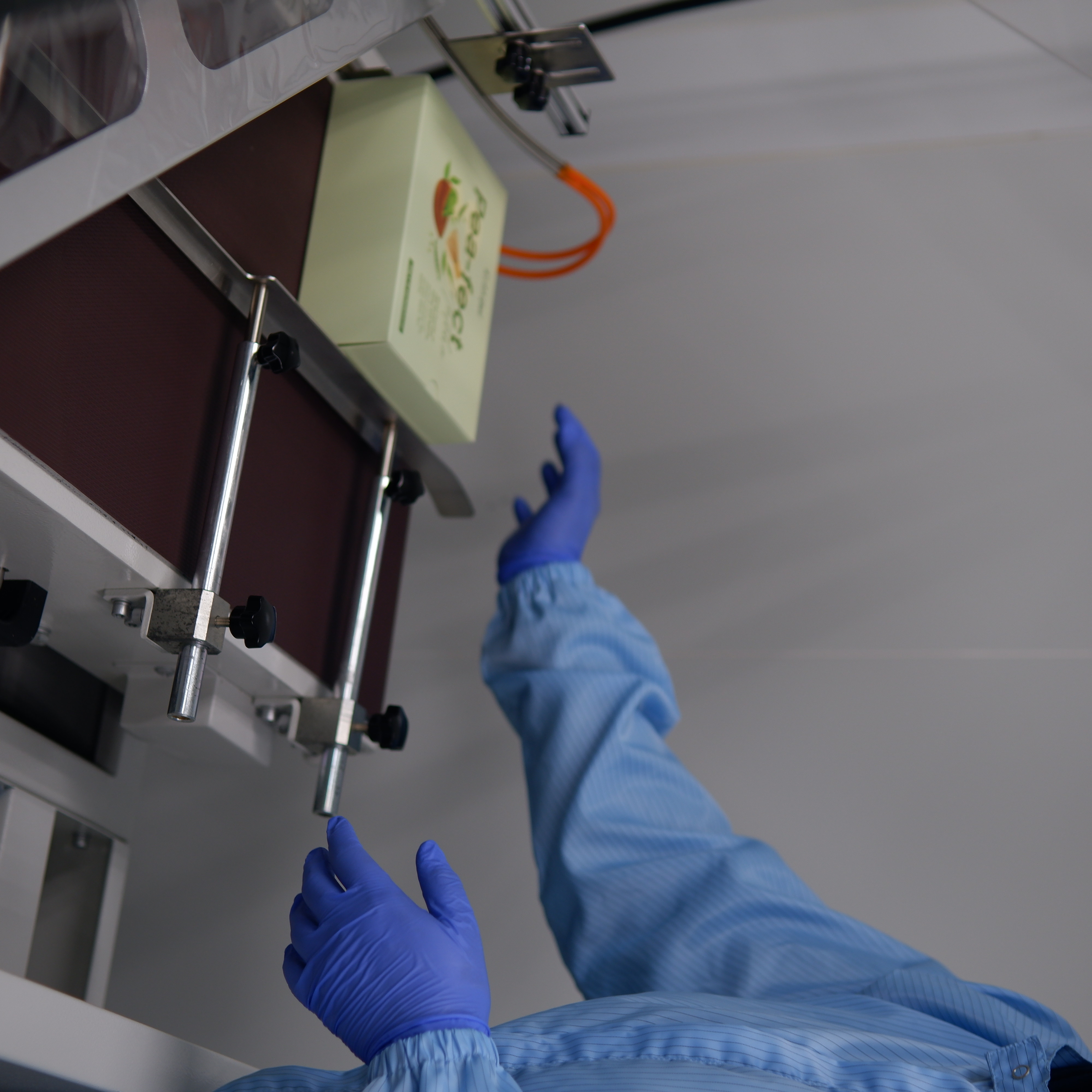

Step 6: Box Folding & Packaging

Each packaging box is carefully folded and prepped to hold our sachets securely. Clean lines, sturdy construction, and precise folds ensure your order arrives in perfect condition. Our trained team hand-packs each sachet into its respective box with care and accuracy. This final step is more than just packing—it’s our way of ensuring every box you receive is professionally presented and ready to fuel your day.

Step 7: Heat Seal & Final Touch

To keep everything fresh and secure, each box is sealed in protective plastic using high-temperature machinery. This final seal ensures hygiene, tamper protection, and travel durability—ready to be delivered straight to your doorstep.